Straight Automatic Rectangular Duct Production Line 5

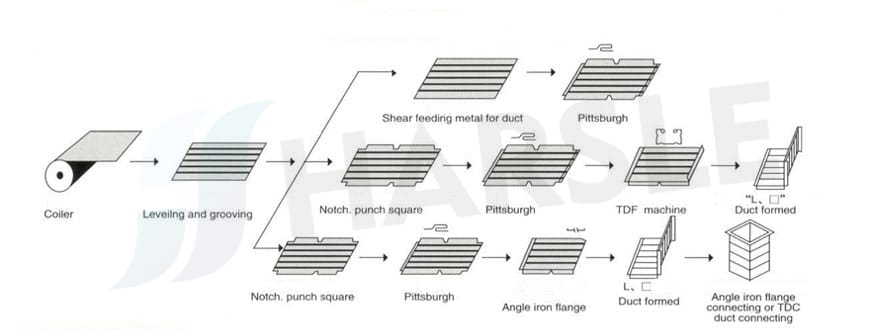

Straight Rectangular Duct Production Line is mainly used for making the square tube by one step forming for HVAC duct manufacturers. Meanwhile, the functions mainly include leveling, beading, notching, cutting, folding, bilaterally angle steel or TDF flange forming, and folding into the square duct.

Sheeting Thickness (mm):0.5-1.5

Max Working Speed (m/min):16

Max Weight Of Sending Coil (T):7×4

Total Power (KW):36

10 in stock

AML-V Rectangular Duct Line

| MODEL | SHEETING THICKNESS (MM) | MAX WORKING SPEED (M/MIN) | MAX WEIGHT OF SENDING COIL (T) | TOTAL POWER (KW) | MAX PROCESSING WIDTH(MM) | SHEARING TOLERANCE(MM) | DIAGONAL TOLERANCE(MM) |

| AML-V-1.2*1250 | 0.5-1.2 | 16 | 7x4 | 36 | 1250 | ±0.5 | ±0.5 |

| AML-V-1.5*1250 | 0.5-1.5 | 15 | 7x4 | 36 | 1250 | ±0.5 | ±0.5 |

| AML-V-1.2*1500 | 0.5-1.2 | 16 | 7x4 | 36 | 1500 | ±0.5 | ±0.5 |

| AML-V-1.5*1500 | 0.5-1.5 | 15 | 7x4 | 36 | 1500 | ±0.5 | ±0.5 |

Performance Features Of Duct Production Line

straight rectangular duct production line AML-V Rectangular Duct production line has the other name: Straight Auto duct production line 5, it is mainly used for leveling, beading, notching,7mm lock forming, TDF/Angle steel flange forming, shearing, folding. and this machine can do the square tube by one-step forming. It is more suitable for workshops with longer venues because of its dimensions. Only with inputting dimensions in HMI, straight production line 5 can automatically complete leveling, beading, punching, shearing, locking, forming TDF / angle steel / C-shaped flange, folding, and at last produce a square duct. The capacity of the day is 1000-2000 square meters.

All the rolling reels are made of bearing steel so that the lifetime will be prolonged. By the way, the injection holes are used on both sides of the drive shaft so that to enhance the bearing life.

AML-V Rectangular Duct production line can withdraw sheet metal automatically. Besides, the auto duct line 5 machine has the material-saving mode. The imported configuration includes the German FESTO cylinder, Taiwan hydraulic system, Taiwan HIWIN guideway, and France Schneider electric system. PLC system is Japan Mitsubishi. Meanwhile, the basic configuration includes two electric material racks (4 material trays, 5-7T each roll), one rack, one main machine (duct line 2 host), one mechanical arm for clutching, locating, and transferring, one lock forming machine, one duplex TDF flange forming machine, one duplex angle steel flange forming machine, one hydraulic folding machine and a set of computer controlling system.

The worker can use the auto duct line 5 machine with other square duct machines, for example, hydraulic/pneumatic/manual-folding machine, lock seam closing machine, corner punching machine, corner assembly machine together to complete the whole duct. The line 5 machine can make a max galvanized sheet of thickness of 1.2 mm. Besides, we can provide engineer overseas service if customers need. straight rectangular duct production line

Main Import Configuration Of Duct Production Line 5

- Japan Mitsubishi PLC system

- Germany FESTO cylinder

- France Schneider electrical system

- Taiwan hydraulic system

- Japan OMERONencoder

- Taiwan HIWIN guideway

Basic Configuration Of Duct Production Line 5

- One electric coil cradle with four material trays

- One leveling and beading equipment

- A hydraulic notching system with four molds of two shapes

- One hydraulic shearing machine

- A movable Pittsburgh forming machine

- One duplex TDF flange forming machine

- One duplex angle steel flange forming machine

- Two mechanical arms

- One hydraulic TDF folding part

- One Electric cabinet of Mitsubishi PLC control system and software

Working Schematic Diagram

Product Photos

| Weight | 500 kg |

|---|---|

| Dimensions | 3200 × 3200 × 3200 mm |

| Duct Type |

Rectangular Duct |

| Function |

Beading ,Cutting ,Flanging ,Folding ,Forming ,Leveling ,Notching |

| Power Source |

Electric ,Hydraulic ,Pneumatic |

| Brand |

HARSLE |

| Delivery Time |

15 Days |

| Payment Term |

LC ,T/T |

| Price Term |

FOB |

| Warranty |

One Year |

Reviews

There are no reviews yet.